- COMPANY

-

SOLUTIONS

WMX

WMXSoftware-based Motion Control Platform

MCX-CM220

MCX-CM220WMX IPC Controller

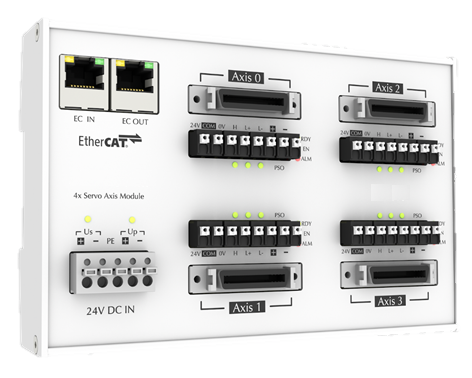

BHY-IO

BHY-IOEtherCAT-based Digital I/O Module

BHY-IO2

BHY-IO2EtherCAT-based enhanced Digital I/O module

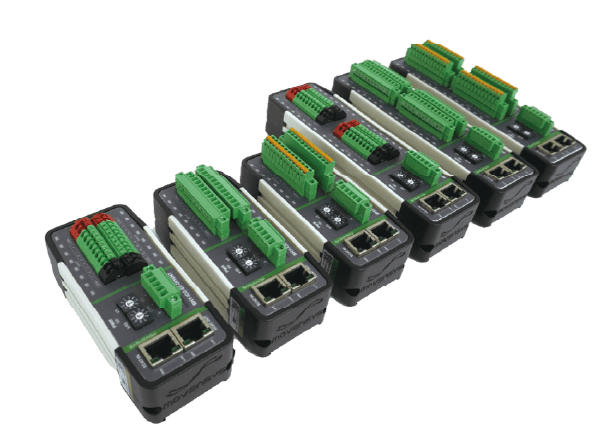

Step EtherCAT Series

Step EtherCAT SeriesMicro Stepping System

StepServo EtherCAT Series

StepServo EtherCAT SeriesClosed Loop Stepping System

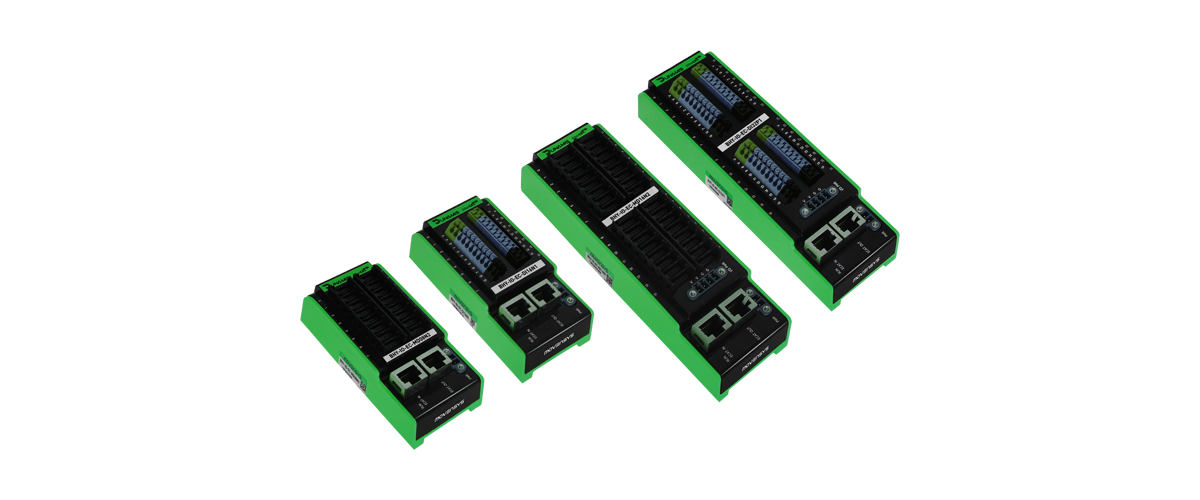

BHY-AX Series

BHY-AX SeriesEtherCAT to Pulse/Trigger Module

VMS-ACS

VMS-ACSSimple Vibration Measurement IoT Sensor Using EtherCAT

- SUPPORT

- RESOURCES

- NEWSROOM

NEWSROOM

News

[NEWS] Movensys, artificial intelligence predictive maintenance software to improve production and quality ↑

- 2022.01.13

- |

- MOVENSYS

- |

- 3,053

Movensys announced that it plans to implement 'artificial intelligence-based predictive maintenance software technology' for manufacturing machinery and equipment and collaborate with various business solutions in the industrial field.

Predictive maintenance is a technology that is widely introduced to secure productivity and quality in manufacturing while preventing machine and equipment failures at manufacturing sites.

However, in practice, it is not easy for companies to introduce technologies and tools related to predictive maintenance. In order for artificial intelligence to be realized, real-time data must be collected and analyzed from equipment, because hardware-based motion control equipment has limitations in securing and providing real-time data.

Movensys' WMX is a software installed on a Windows PC that can control manufacturing equipment through network communication. Because it is a software-based motion control solution, it has accumulated various device control and real-time data and secured predictive maintenance technology by linking the data pipeline.

In particular, as WMX itself can act as an edge computing, it enables predictive maintenance while managing and analyzing data in real time by linking directly with artificial intelligence programs on the cloud.

This technology was also proven by ‘development of AI predictive maintenance software for real time motion control AGV and AMR’, an AI voucher support project jointly researched by Movensys with Daim Research and KAIST.

Previous

Previous

Next

Next