NEWSROOM

Blog

[Movensys Column] What Does It Take to Build a Real Smart Factory? (Juyoung Song, CSO of Movensys)

- 2025.08.27

- |

- 최고관리자

- |

- 1,225

What Does It Take to Build a Real Smart Factory?

The concept of the “smart factory” was first introduced at Germany’s Hannover Messe in 2011, together with the German government’s Industry 4.0 initiative. At that time, the government defined a smart factory as an intelligent factory operation system that achieves industrial digitalization through factory automation and the use of digital information acquired from it.

Fifteen years later, what do today’s factories actually look like? The fully automated plants we once envisioned—where diverse products are manufactured solely through digital orders without human operators, and where factories autonomously solve problems—remain far from reality. In practice, factories still rely heavily on human labor, and process automation is largely confined to mid- to large-sized enterprises with sufficient capital.

As the working population shrinks and labor costs continue to rise, manufacturers in Korea have historically relocated production bases to low-cost countries (LCCs). Recently, however, instability in global supply chains has underscored the importance of reinforcing domestic production capacity. The problem is that a labor-dependent production structure makes it difficult to resolve high labor cost issues.

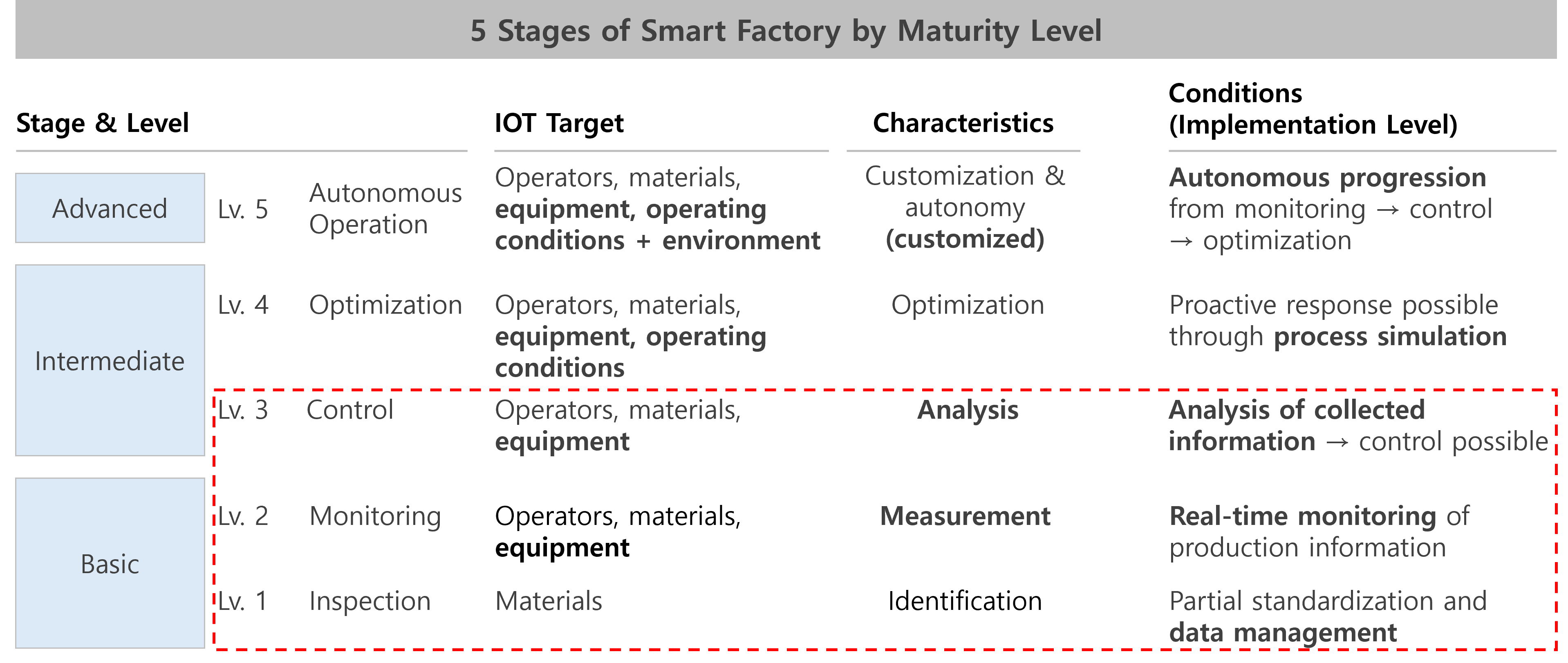

To address this, the government-led Smart Manufacturing Innovation Promotion Team has defined five stages of smart factory development, specifying the maturity levels and characteristics of each (Figure 1). What is most noteworthy are the initial stages (1–3), which lay the foundation of a smart factory: collecting and managing operational data in standardized formats, and using this to build an automation-ready base for optimized operations.

Figure 1. Definition of stages for building a smart factory (Source: Smart Manufacturing Innovation Promotion Team website)

Two key conditions are required:

1. Production data must be captured in digital form.

2. The collected data must be processed in real time and reflected in the control system.

The essential data include materials, equipment, and operators. Materials and equipment can be relatively easily quantified using design and specification values, but operator-related data involve qualitative factors such as skill level and physical condition, making them difficult to standardize. The practical solution is therefore to minimize dependence on human labor and build an automated equipment operation system to the fullest extent possible.

The Role of Motion Control in Smart Factories

At the core of automated production systems is the motion controller—the “brain” of the system. It delivers motion commands to each actuator with precise timing and determines subsequent actions based on the results. Stable production yield requires highly reliable control performance, but for a smart factory this is not enough. It must also support real-time production data collection, standardized data acquisition, and process optimization based on that data.

In other words, motion control forms the foundation for advancing beyond simple automation toward “intelligent operation,” where efficiency is improved, quality is managed, and predictive maintenance is realized through data.

Traditionally, the factory automation (FA) industry has relied on general-purpose motion controllers (PLCs) supplemented by additional modules or PCs to deliver data to higher-level IT systems such as MES and ERP. While this long-established configuration may feel familiar on the shop floor, it is also one reason why productivity improvements have plateaued. Moreover, PLCs and hardware controllers face inherent limitations in data handling and computational capacity, making close interaction between IT and OT structurally difficult.

This structural barrier prevents the data-driven optimization that smart factories require. Overcoming it demands a new architectural approach and genuine IT–OT convergence. A smart factory must be understood as an ecosystem: in the OT domain, reflexive, real-time control at the millisecond–microsecond level must be ensured, while in the IT domain, large-scale data collection and analysis should enable intelligent control (e.g., AI) based on learning and experience.

Therefore, a motion controller designed for true smart factories must deliver:

1. Real-time stability and highly reliable control performance

2. Real-time, large-scale data collection for equipment intelligence

3. An open platform structure that allows seamless integration with diverse ICT technologies

The most effective approach is to integrate all these functions into a single software solution. Unlike conventional software, however, it must be designed to guarantee real-time performance and optimized inter-module connectivity. It must also adopt an open architecture to integrate with other ICT technologies. Because equipment configurations, products, and communication protocols vary across manufacturing sites, at least one to two years of field stability testing are required. Furthermore, the foundation must be in place for AI to analyze real-time large-scale data to improve yield, optimize processes, and enable predictive maintenance.

Ultimately, the most rational choice is a software-based motion control solution that has been designed with these factors in mind and proven stable through long-term mass production.

The Future of Motion Control with AI

Motion control will continue to evolve into software-centric solutions integrated with AI. While it is uncertain which specific technologies will transform factories in the years to come, what is certain is that AI will inevitably be embedded in production equipment and operations. As such, motion control solutions will increasingly be based on open-architecture software capable of fully embracing AI technologies.

Analyzing real-time production big data with AI, so that equipment and factories autonomously optimize and improve themselves—this is the true smart factory we have envisioned.

Movensys’s Response and Technology Development

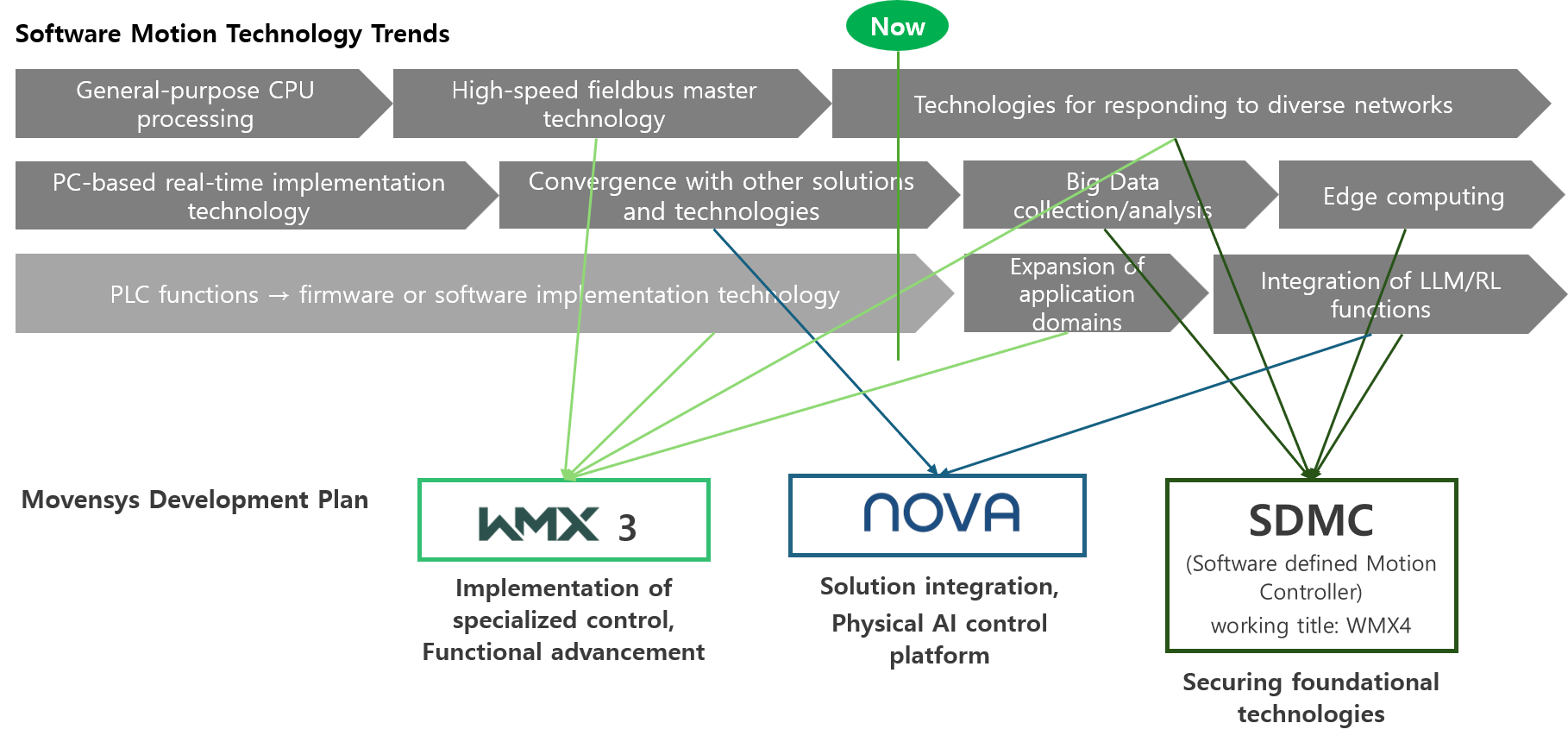

Movensys identifies the core role of motion control in smart factories as “real-time, data-based optimized control combined with AI integration.” To this end, the company is pursuing the following activities (Figure 2):

Figure 2. Movensys technology development direction (Source: Movensys R&D roadmap)

- Equipment level: Enhancing the motion control functions of WMX and improving user convenience

- Robot integration: Controlling autonomous mobile robots through NOVA, with future integration into LLM collaboration functions

- Cloud AI: Developing SDMC (Software Defined Motion Controller) integrated with reinforcement learning (RL)

Movensys envisions a smart factory where WMX optimally controls process equipment, NOVA orchestrates mobile robots (MoMa), and at the top level, SDMC manages and optimizes the entire control solution (Figure 3). In this model, digitized real-time big data is analyzed and leveraged by AI, enabling factories to autonomously advance their operations—what we call the real smart factory.

Figure 3. Movensys’ smart factory concept (AI-generated image)

Ultimately, motion control technology is the core driving force of smart factory innovation, and Movensys will continue to lead the future of manufacturing through it.

- Contributor: Juyoung Song, CSO of Movensys

Previous

Previous

Next

Next