NEWSROOM

Blog

[Movensys Column] Controller Requirements for Using AI in Smart Factories

- 2025.12.12

- |

- 최고관리자

- |

- 455

1. Shift in Industrial Paradigms

Over the past decade, the manufacturing industry has established data-driven production management systems through Digital Transformation (DX). As data collection and monitoring have been automated across various domains—including production, quality, equipment, and logistics—factory operational efficiency has significantly improved.

However, today’s manufacturing sites are moving beyond simple “digitization” and entering a stage of AI-based autonomous intelligent operation. With the introduction of AI technologies, process data is collected and analyzed in real time, and the results are immediately reflected in control commands, advancing toward automated decision-making in process operations.

In other words, the industry is evolving into a stage where intelligent automation is realized based on digitized data.

2. The Role of Controllers in Smart Factories

A smart factory is a manufacturing operation system in which OT (Operational Technology) and IT (Information Technology) are organically integrated. OT systems controlling physical processes such as equipment, robots, and sensors are connected with upper-level management systems (IT) such as MES and ERP, enabling decision-making based on real-time production data.

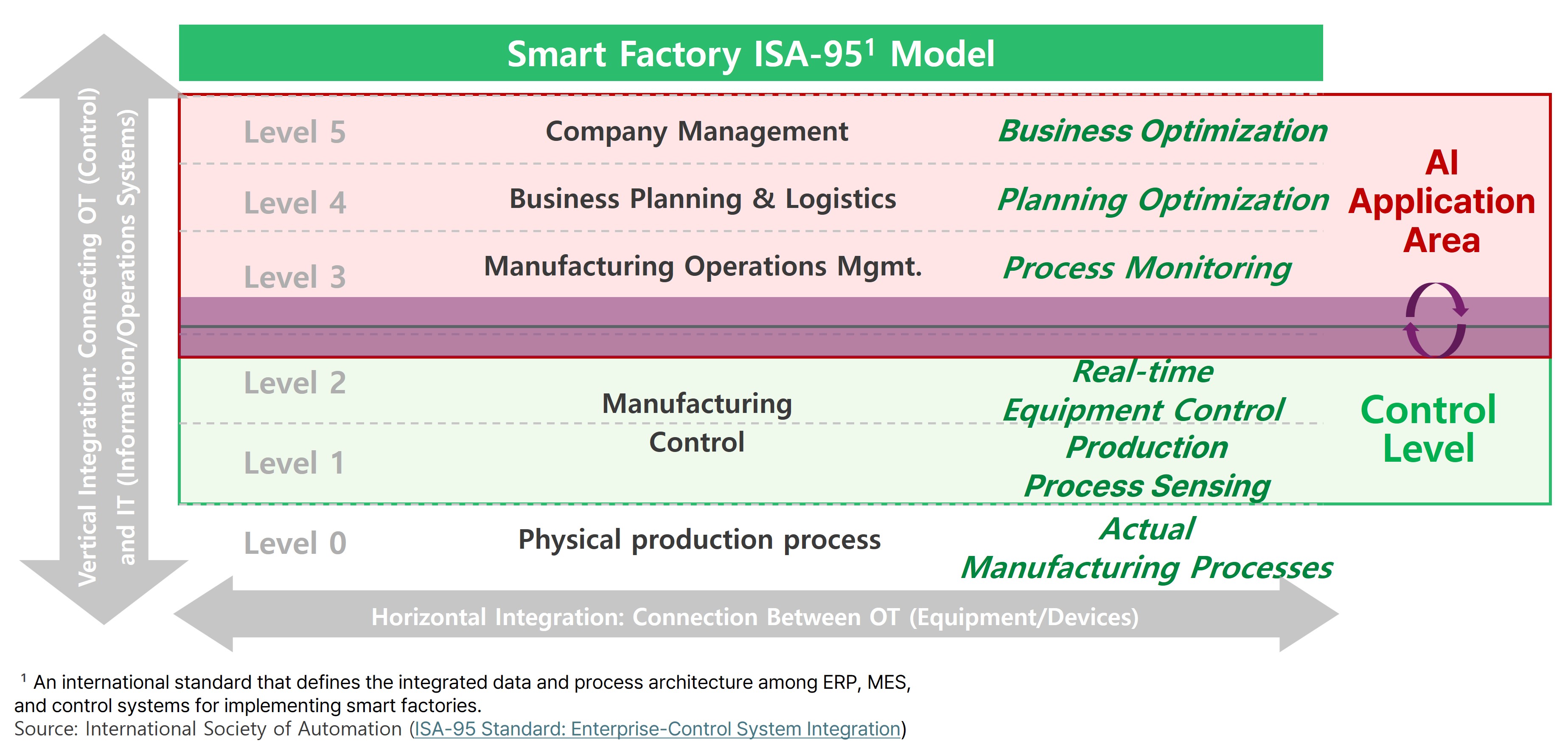

Figure 1. Smart Factory ISA-95 Model, AI Application Area, and Control Level

The international standard ISA-95, which systematically explains this integrated structure, defines the hierarchical structure of manufacturing operations from Level 0 to Level 5 and clearly specifies data flows and interfaces between levels. Covering the entire process from physical production execution (Level 0) to enterprise management (Level 5), it serves as a fundamental reference model for implementing smart factories.

In the ISA-95 hierarchical structure, Levels 0–2 constitute the field operation levels where production processes are executed and equipment is controlled, responsible for real-time responsiveness and precision on the shop floor. Levels 3–5 cover areas such as process data analysis, prediction, production planning, and operational optimization—areas where AI technologies are currently applied.

Recently, smart factory technologies have expanded into the overlapping zone where these two domains meet, meaning a structure in which AI analysis results are reflected in control stages in real time. In this zone, the controller goes beyond simply driving equipment: it collects and preprocesses process data in real time, provides it in a form suitable for AI analysis, and converts the resulting decisions immediately into control commands to enable autonomous process control.

This indicates that controllers are evolving beyond devices that operate lower-level equipment within individual processes, becoming core platform-level nodes that connect, analyze, and control production and operational data in real time.

3. Controller Technology Requirements in the Era of Intelligent Automation

As AI and data analytics technologies become fully applied to control operations, controllers in the era of intelligent automation must control complex production processes in real time while ensuring stable interoperability among various equipment and systems.

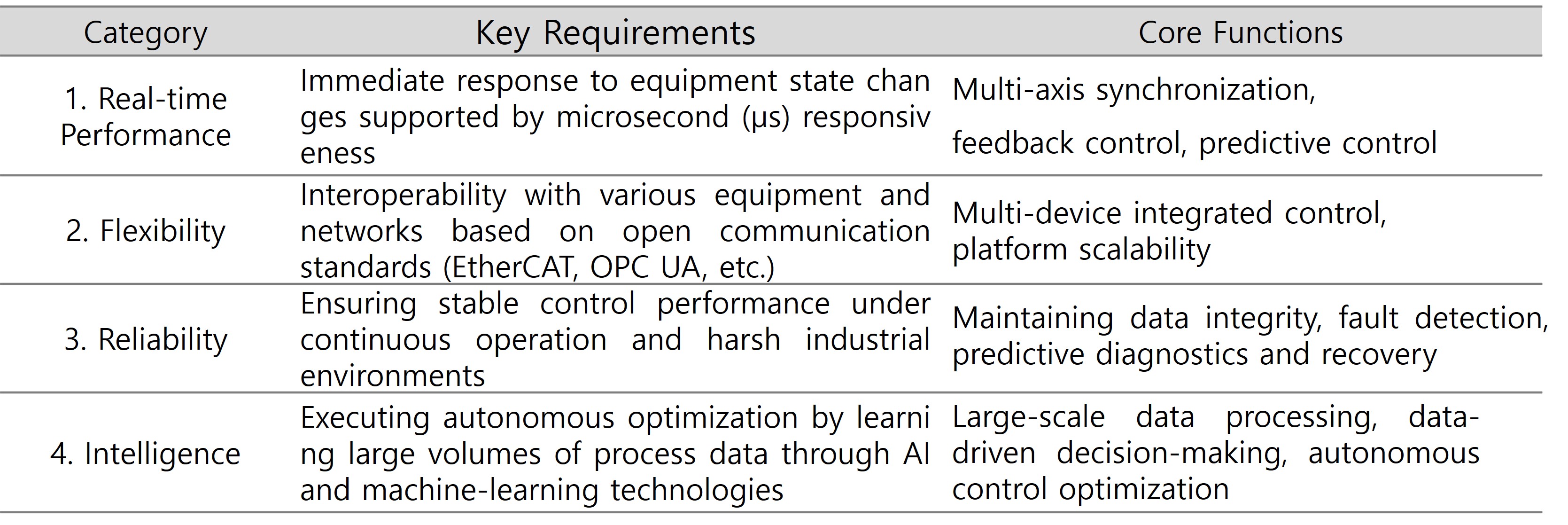

The essential technical requirements needed to meet these demands are classified into real-time performance, flexibility, reliability, and intelligence.

Table 1. Key Requirements and Core Functions of AI-Based Smart Factory Controllers

Real-time performance is a fundamental requirement for high-speed, high-precision process control. Controllers must ensure microsecond (μs)-level response times, enabling them to immediately reflect subtle equipment state changes and perform multi-axis synchronization and predictive control. This directly affects the dynamic stability of production equipment and the precision of product quality.

Flexibility is a core factor for responding to diverse manufacturing environments. Based on open communication standards (EtherCAT, OPC UA, etc.), controllers must support interoperability with various equipment and networks, reducing complexity during system integration and providing structural flexibility to accommodate future facility expansion or changes.

Reliability is essential in industrial environments where production equipment operates continuously for long periods. Control systems must maintain stable operation under physical influences such as temperature, vibration, and electromagnetic interference, while ensuring data integrity and consistency. Strengthening control-logic verification systems and diagnostic capabilities is also crucial to minimize unpredictable system behavior.

Finally, intelligence refers to the controller’s capability to analyze process data in real time through linkage with AI and machine-learning technologies, and to autonomously optimize control performance by reflecting the results into control logic. Through big-data processing, controllers can integratively analyze data collected from sensors and equipment, detect anomalies early, predict factors affecting quality variations, and execute data-driven decision-making.

As a result, controllers are evolving from simple command executors to execution platforms that perform intelligent decision-making and control in real time.

These technical requirements call for a control architecture that enables organic integration with advanced technologies such as AI, data analytics, and digital twins. Consequently, the transition to software-based motion control is accelerating across the industry.

Software-based motion control secures microsecond (μs)-level responsiveness through real-time operating systems (RTOS) and real-time communication (e.g., EtherCAT) centered on industrial PCs (IPC). Additionally, it integrates motion, robotics, vision, I/O, and safety control within a single platform, simplifying hardware configuration and enhancing maintenance efficiency. This structure also facilitates data connectivity with upper-level technologies such as AI, digital twins, and edge computing, increasing the overall intelligence of manufacturing systems.

Today, the competitiveness of control technology is determined by the ability to integrate AI with real-time control logic. Accordingly, software-based high-performance control platforms that analyze and interpret data to optimize processes—and connect this directly to real-time control—are emerging as key technologies for next-generation automation.

4. Application Cases of Software-Based Integrated Control

Control technology in the manufacturing industry is rapidly shifting to software-based integrated control. In fields requiring complex equipment and high-precision processes—such as semiconductors, electronics, and logistics—software-based motion control architectures based on industrial PCs (IPC) are being applied to supplement and extend existing control structures.

This technological transition provides a foundation for integratively carrying out data collection, AI analysis and optimization, and real-time control execution within a single platform, enhancing process real-time performance, precision, and flexibility.

Key implementation cases in real industrial environments include the following:

(1) Software-Based Integrated Control for Semiconductor OHT and STK Systems

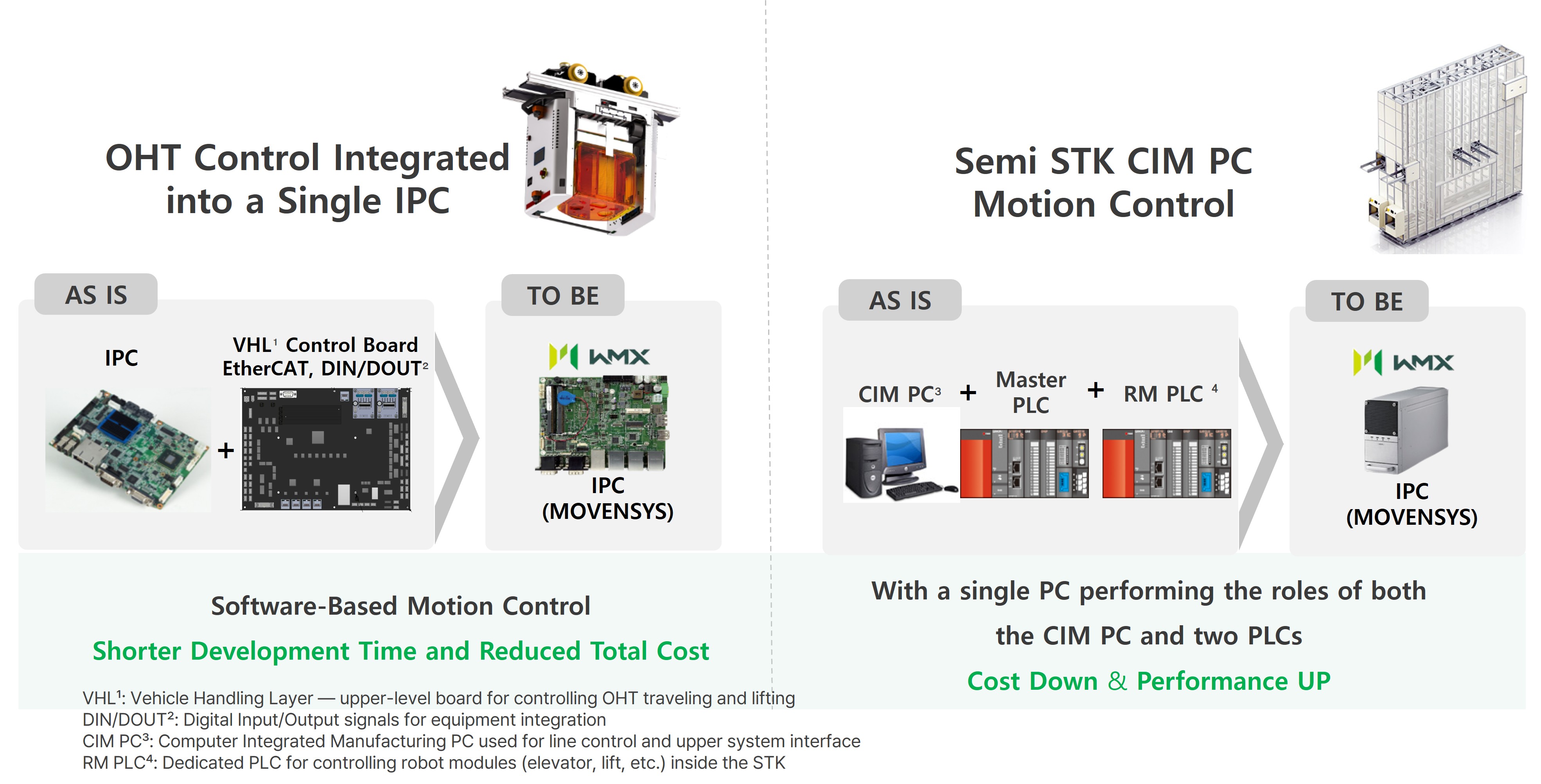

In semiconductor manufacturing and logistics processes, various equipment must interoperate in complex ways, often causing communication delays and structural complexity. In such environments, simplifying control platforms and ensuring communication efficiency directly influence system performance and maintainability.

Traditional OHT systems were built by combining an IPC with separate VHL control boards (EtherCAT, I/O boards, etc.). By performing all motion and I/O control within a single IPC using a software-based motion controller—without separate control boards—development time was shortened, total cost reduced, and system configuration simplified, significantly improving scalability and maintainability.

Similarly, traditional semiconductor STK equipment used three separate units: a CIM PC, a Master PLC, and an RM PLC. This structure caused complex control flows and potential performance degradation due to communication delays. By transitioning to a unified IPC-based integrated control architecture, communication delays were eliminated, and maintenance and upgrade efficiency improved significantly.

Performing both motion and logic control within the same software environment secured real-time control stability and data synchronization between processes.

Figure 2. Transition to Single-IPC Integrated Control Architecture for OHT and STK Equipment

(2) One-PC Integrated Control for Mobile Manipulators (MoMa)

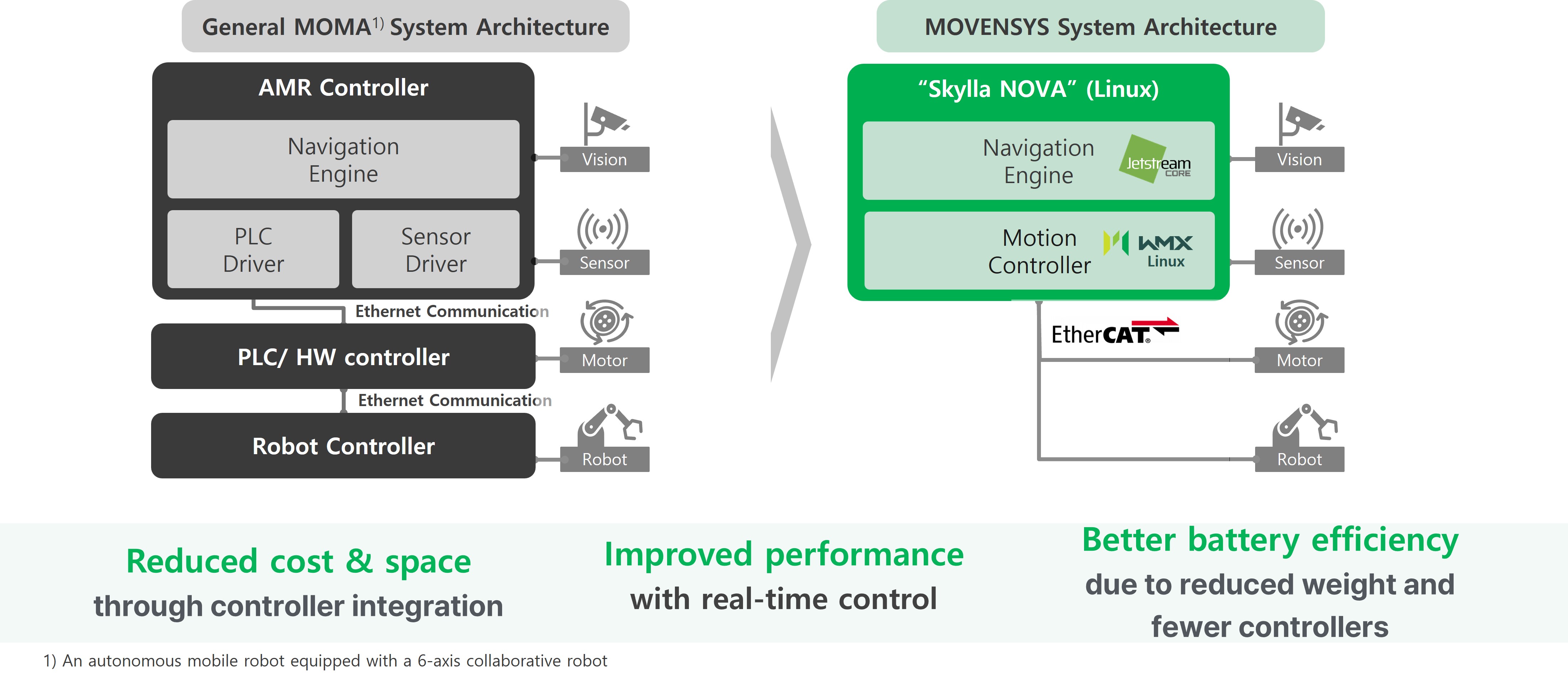

A Mobile Manipulator (MoMa) is a system consisting of an autonomous mobile robot (AGV) equipped with a 6-axis collaborative robot. Traditionally, multiple controllers—such as the driving controller and robot controller—were connected via Ethernet, each responsible for different functions.

By applying a single-PC software-based integrated control structure, driving, robot motion, and vision-sensor control were performed on one platform. This reduced system size and power consumption, while real-time synchronized control significantly improved driving stability and task precision.

Figure 3. Integrated Control Architecture for MoMa Systems

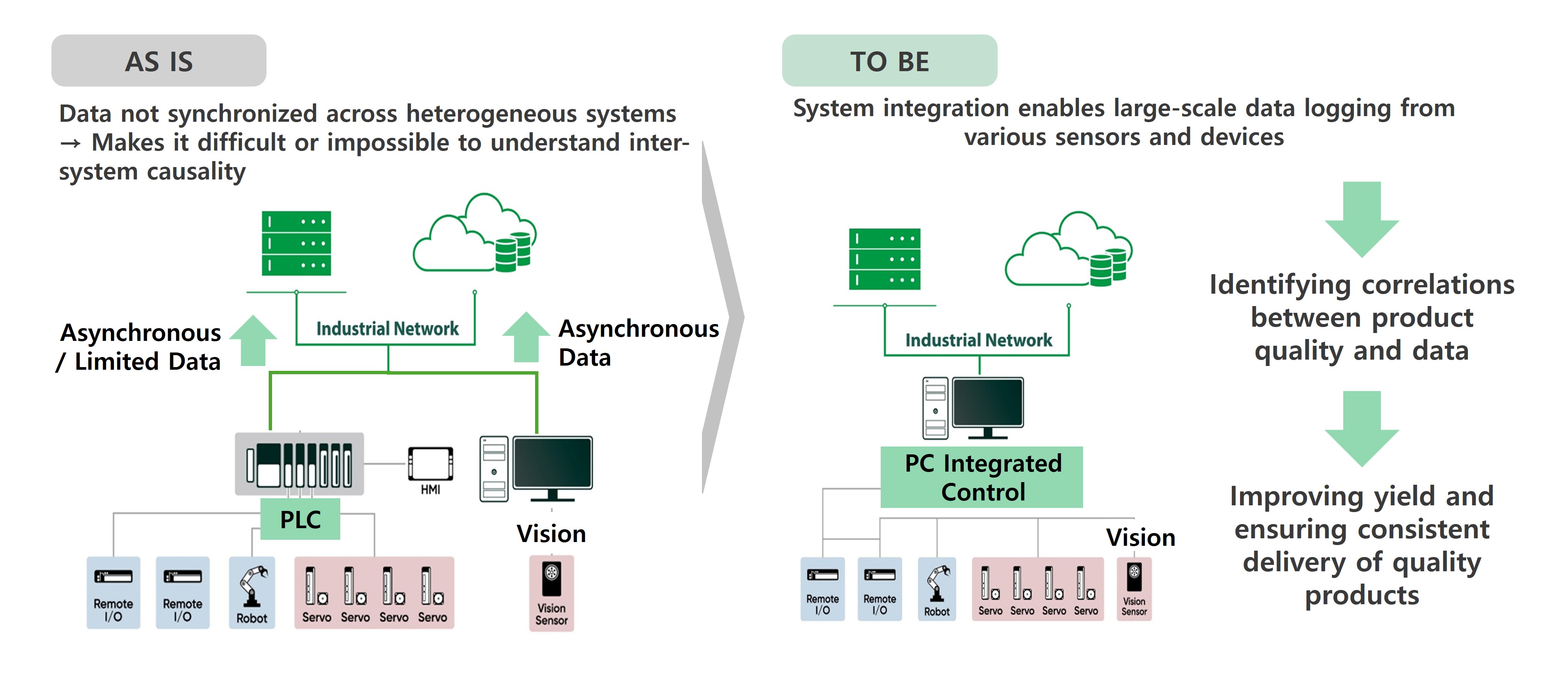

(3) Transition from PLC to PC-Based Software Control Platforms

In an electronics assembly line, replacing the PLC-based control system with a PC-based control platform enabled real-time collection of sensor and equipment information and allowed large-scale logging. As a result, defect-prediction and process-optimization models were applied directly during operation, ultimately improving yield and stabilizing the production of quality goods.

Figure 4. Transition from PLC-Based Control Systems to PC-Based Software Control Platforms

These cases show that software-based integrated control technologies have been practically applied and validated across various manufacturing environments, producing tangible results in real-time control of production equipment, data synchronization, and maintenance efficiency. Furthermore, these technologies promote interconnection among controllers, sensors, AI, digital twins, and other advanced technologies, becoming key technical infrastructure for realizing intelligent automation across industries.

5. Conclusion: The Future of Intelligent Manufacturing Enabled by Integrated Control

The evolution of smart factories has moved beyond discussions of automation between individual devices. The structure is now shifting toward an integrated system in which data, AI, and control technologies work together in real time.

In environments where AI analyzes process data and its results are directly reflected in control logic, the controller serves as a core node connecting decision-making and execution, rather than simply functioning as an equipment driver.

Software-based integrated control technology serves as the technical infrastructure enabling this transformation. By minimizing hardware dependency while maintaining high-precision, high-speed control—and by enabling real-time integration with upper-level technologies such as AI, digital twins, and edge computing—it provides a foundation in which data collection, analysis, and control execution occur within a single feedback loop.

This structure shows that “control” is no longer a terminal function in the process but is evolving into a platform that learns from data and performs optimization at the center of intelligent manufacturing.

Ultimately, industrial competitiveness will depend not only on AI’s analytical capability but also on how quickly and reliably analysis results can be reflected in actual systems. Accordingly, software-based integrated control technology—by merging AI and control—presents the path forward for the advancement of industrial automation and practically supports the transition to intelligent manufacturing systems.

- Contributor: Keehoon Kim, CEO of Movensys

Next

Next